Request A Free Consultation

Request A Free Consultation

Friulinox Ready RBS-081-SA

Ready blast chiller/freezer. Takes up to 8x 1/1GN or EN1 trays. 40Kg chilling and 25Kg freezing capacity.

Ideal for Restaurants, Pubs, Hotels, and Food Manufactures

Performance and Quality

Hard-O-Tronic®: The electronic control system that allows you to easily change the consistency of the shake according to the type of product inserted or desired style.

Start Up Phase

Gravity MIX FEEDING SYSTEM

High Efficiency Helical Beater

Direct expansion cylinder

Convenience

Tank Agitator

Adjustable dispensing speed

Scan the QR Code on the front of the machine to access the most up to date equipment information: Instruction Manual, Carpi Care kit & Carpi Clean kit.

Savings

New high-performance electric gearmotors and condensers

Safety

More operational safety and more control during production

Hygiene

Easy cleaning, guaranteed hygiene

| Model |

Friulinox RBS-081-SA |

| Dimensions (W x D x H) |

790 x 870 x 1460 mm |

| Yield per cycle +90/+3°C |

40 Kg |

| Yield per cycle +90/-18°C |

25 Kg |

| Tray capacity |

8x 1/1GN or EN1 trays (65mm) |

| Refrigeration |

R290 |

| Cooling power |

1127 W |

| Cooling method |

Air cooled (water or remote on request) |

| Voltage |

230v / 50hz / 1ph |

| Fuse / CB rating | 13 amp |

Functions of the Ready range

- Soft or hard chilling to +3°C

- Soft or hard freezing to -18°C

- Continuous Cycle from -5°C to -40°C

- Storage either positive (-2°C / +18°C) or negative (-18°C / -21°C)

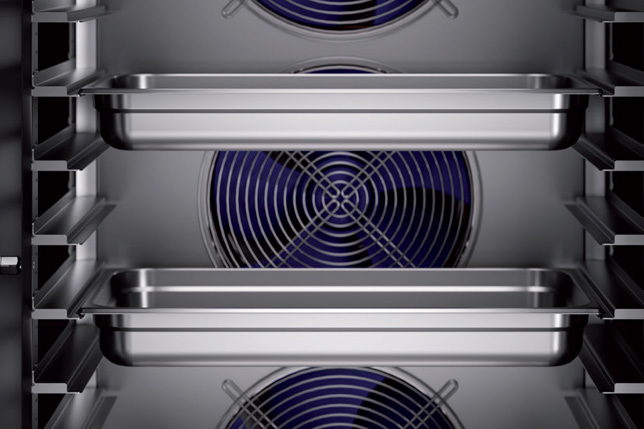

Flexible tray configuration

The Ready range of cabinets allow you to blast chill/freeze food in either full size 1/1 Gastronorm trays or standard EN1 baking grids (600x400mm) at the same time without the need for any additional or special racking.

Features of the Friulinox RBS-081-SA include:

External construction

• 0.8 mm-thick stainless steel external sides and door (Scotch-Brite satin finish)

• Stainless steel internal coating with fully rounded corners

• Die-moulded and leakproof internal base

• Full-length flush ergonomic handle

• 1 mm-thick stainless steel top (Scotch-Brite satin finish)

• HCFC-free high-density polyurethane foam insulation (approx. 42 kg/m³)

• Anti-condensation heating element situated on the body frame, under the stop

• Magnetic seal on 4 sides of the door

• Stainless steel exterior (Scotch-Brite satin finish)

• Indirect-flow electric fans – made of composite material – on the product

• Cooling capacity expressed at evaporation temperature -25°C and condensation temperature at +45°C

Interior features

• Quick-release heated core probe with 4 measuring points

• Removable stainless steel double-track guides (GN-EN), equipped with an anti-tip system. (Grids sold separately)

• Side guide-supporting uprights with 18 mm-pitch holes.

Controls

• 5″ high-definition TOUCH display

• Pictogram and text-identifiable processes

• USB connection for uploading and downloading data/recipes

• Compressor-protecting automatic-reset thermal circuit breaker

• Wifi connectivity (optional)

Performance Tested to European Standard EN17032

All Friulinox Blast Chiller and Freezers are fully tested using a ‘real world’ product to ensure all capacity and performance figures are achievable by the operator.

Performance – the performance test was performed with mashed potatoes in a GN1/1 H40 mm tray, with the mashed potatoes being 35 mm thick, equal to ~5 kg per tray, with blast chiller in a room measured at 30°C.

Chilling consumption – The specific blast chilling consumption expressed in kWh/kg was taken starting with an average mashed potato temperature of 65°C, arriving at +10°C at the end of blast chilling and in less than 120 minutes.

Freezing consumption – The specific consumption in quick deep freezing expressed in kWh/kg was taken starting at an average mashed potato temperature of 65°C, arriving at -18°C at the end of deep freezing and in less than 270 minutes.

Please download the specification sheet for full details of this specific machine.